Things have been busy, and not always with the poor XJS. It's been languishing a fair bit lately due to other things requiring my attention and plain old apathy!

The big repair on the driver's door is also done and that door is just about ready for some epoxy primer. it's been filled and faired, no photo of that at the moment.

Both front guards have also been stripped and temporarily bolted to the shell to allow for fitting and some fairing of some previous repairs and dings. I find it much easier to work on the guards when they are bolted down in position. They are such small, light panels that they move around too easily on stands, benchtops etc. Bolting them up allows you to lean on the sanding blocks properly. Once they are done, they'll be pulled off and epoxied inside and out. I'm quite proud of my plastic sheets masking everything else off! They prevent the guards contacting nice fresh paint, easily allow the fasteners to be pushed through them and keep everything dust free. I came across the idea by accident, I offered the front guard up for a trial fit with the plastics still on and it just looked right.

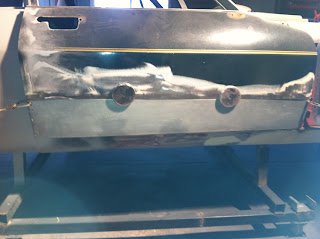

The boot lid is also stripped inside and out. Chemical stripper on the outside, wire wheel on the inside. Don't use chemical stripper on inside of panels, there is no way to remove it all once it gets behind the subframe.

This is the first panel I have come across that hasn't been repaired in the past or to have dents.

When I pulled the bootlid off my donor car, I found this on the original fuel tank. Kind of puts the whole "disgruntled union workforce" story about Brown's Lane into perspective...at least one person on the line was either enjoying their job or building the new Jaguar two door...

And that's where we are at the moment. I'm off as soon as I post this update to fair and fill both front guards and the passenger side door. Will hopefully have both guards, door and bootlid in epoxy (and hopefully high fill also) before christmas. I haven't started stripping the bonnet yet, it's such a large panel I'm leaving it until I am ready to paint everything else to bring it into the garage and prep it. it just takes up too much space!

Small update today. I managed to get the two front guards and boot lid in epoxy primer. Have thoroughly cleaned and primed inside and out all panels, so I shouldn't have any rust issues with the front guards once they have seam sealer applied to the reinforcement seams.

The boot lid has come up really well, there is a tiny little ding in it that may just block out with primer I think.

I also ended up with a spare front guard off the parts car and will also have an extra door eventually.

I spent an afternoon pulling engine bay parts out of the parts car.

The brake master, all fluid lines, proportioning valve etc will all get thoroughly cleaned and reconditioned before being installed. This way I'll know how much room everything needs and it won't have to come out again once the engine is in. Nothing looks nicer than nice clean, new master cylinders, boosters, brackets and lines.

Everything on the parts car looks in reasonable condition and looks to have been in service until fairly recently. It all just needs a good clean.

And I received a rear sump HQ pickup for the Holden V8. I picked up a nice used rear sump a while ago so now the engine can be swapped over to rear sump for the conversion. I intend to remove the late model front sump baffling and windage tray from the Commodore sump and fit it to the older sump. Both the sump and pickup I bought are in excellent used condition.

The engine will get new front and rear main seals while I'm at it as well, plus I'll pop the transmission off, replace the front pump and input/converter seal plus some other light transmission tweaks.

I may as well replace seals etc now whilst it's easy.

It's very easy to say "just strip the paint" but anyone who has done it knows how tedious, tiring, noisy, smelly and dirty it is. A very easy job to keep putting off. I've got both sill panels looking great and everything on the shell is now in high fill ready for somfinal sanding. Sill panels are HORRIBLE things to get straight- they're down low and weird angles.

The big repair on the driver's door is also done and that door is just about ready for some epoxy primer. it's been filled and faired, no photo of that at the moment.

The boot lid is also stripped inside and out. Chemical stripper on the outside, wire wheel on the inside. Don't use chemical stripper on inside of panels, there is no way to remove it all once it gets behind the subframe.

This is the first panel I have come across that hasn't been repaired in the past or to have dents.

Small update today. I managed to get the two front guards and boot lid in epoxy primer. Have thoroughly cleaned and primed inside and out all panels, so I shouldn't have any rust issues with the front guards once they have seam sealer applied to the reinforcement seams.

The boot lid has come up really well, there is a tiny little ding in it that may just block out with primer I think.

I also ended up with a spare front guard off the parts car and will also have an extra door eventually.

I spent an afternoon pulling engine bay parts out of the parts car.

The brake master, all fluid lines, proportioning valve etc will all get thoroughly cleaned and reconditioned before being installed. This way I'll know how much room everything needs and it won't have to come out again once the engine is in. Nothing looks nicer than nice clean, new master cylinders, boosters, brackets and lines.

Everything on the parts car looks in reasonable condition and looks to have been in service until fairly recently. It all just needs a good clean.

I may as well replace seals etc now whilst it's easy.