The front and rear suspension have been freed from the donor car. It's actually a fair bit rustier than it looks once you look past the bog that's been slathered over rusty frame rails....

Anyway, that car won't be on the road destroying poor unsuspecting people's bank accounts anymore!

Here are the front and rear ends from the donor car. I'll strip them of all suspension and brake parts to make them easier to handle under the car for mock up, then once I have the engine positioned and mounts fabricated, they'll come out and go off for blasting, then the suspension and brakes will be reconditioned as they are reassembled. As you can see, the car was a previous dodgy V8 swap victim, so I already have some appropriate front springs for the car:

The sub assemblies are in quite good condition. Even all the crossmember attachment bolts are in great, rust free condition and the rear control arm front mounts literally popped off the body mounts once the bolt was undone with just the gentlest of prying, so I think I've been lucky with these assemblies. One rear hub has a fair bit of play, but nothing a new set of bearings won't fix. The Kent wheels are in very good condition as well, one even has the original, or a period fitted Dunlop Aquajet still on it! Looking at this tyre, I know why so many people were afraid of driving in the rain in the 70's!

I also dragged the engine and transmission out of it's hidey hole for a blast and degrease when I did the crossmembers. They both look in very good condition for their mileage, draining fluids showed both engine and trans had been at the very least serviced somewhat regularly. I had planned on painting at least the engine, but it looks quite reasonable. The rocker covers and intake may get a coat of paint, but that's about it I think:

The factory cast exhaust manifolds look like they may even work as well. I have spent some time untaping the engine wiring harness, the Commodore the engine comes from has a major sub harness running across the front of the engine for power feeds for various relays, ECU power etc. As I will be picking up my power and grounds from the firewall for the ECU, I am bringing most of that wiring back to the left hand firewall area. I will use the stock Jaguar wiring, relays etc for starter, supplying switched power to ECU, ignition module etc, but will use the new ECU to trigger A/C clutch, cooling fans and anything else I may be able to use. I also will be using some of the Jaguar engine harness for various sensor wiring as I plan to carry over the Jaguar coolant gauge sensor at the very least and will splice into the jaguar wiring for warning lights etc.

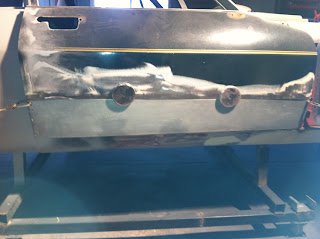

I've also whipped up some covers out of quilted cotton for the car. The side covers have 20mm laminated open cell foam below the crease line in the body in pockets to help protect against accidental dings etc when in the garage being worked on. They'll also probably see service when the car is laid up for any length of time in the future. The cowl cover will get used a lot for regular servicing. Once the car is completed, I will cover that with a layer of vinyl so it is resistant to grease and oils.

The few hours it took to make these covers up is well worth it for the peace of mind they provide me with:

Anyway, that car won't be on the road destroying poor unsuspecting people's bank accounts anymore!

Here are the front and rear ends from the donor car. I'll strip them of all suspension and brake parts to make them easier to handle under the car for mock up, then once I have the engine positioned and mounts fabricated, they'll come out and go off for blasting, then the suspension and brakes will be reconditioned as they are reassembled. As you can see, the car was a previous dodgy V8 swap victim, so I already have some appropriate front springs for the car:

I also dragged the engine and transmission out of it's hidey hole for a blast and degrease when I did the crossmembers. They both look in very good condition for their mileage, draining fluids showed both engine and trans had been at the very least serviced somewhat regularly. I had planned on painting at least the engine, but it looks quite reasonable. The rocker covers and intake may get a coat of paint, but that's about it I think:

I've also whipped up some covers out of quilted cotton for the car. The side covers have 20mm laminated open cell foam below the crease line in the body in pockets to help protect against accidental dings etc when in the garage being worked on. They'll also probably see service when the car is laid up for any length of time in the future. The cowl cover will get used a lot for regular servicing. Once the car is completed, I will cover that with a layer of vinyl so it is resistant to grease and oils.

The few hours it took to make these covers up is well worth it for the peace of mind they provide me with: