You may remember the big hit this car took on the passenger side front sill. My parts car has a decent sill so I've harvested the front of the sill and the closing panel off it.

I'd previously repaired and fabricated a new piece for the inner sill before replacing the floor panels.

So, we've gone from this:

A bit of pushing:

A bit of bashing:

Repaired the inner sill:

And cut out the old piece, after carefully measuring and cutting out a piece from the donor car:

Ignore the crumpled piece of inner sill there, it's been plated over from the inside! Also note the massive angled plate that runs down directly from the inside of the outer A pillar and is welded to the outer sill. This was clearly meant to be a jacking point and is probably a carry over from the Mk X with the jack points inside the sills. Based on this, I conclude jacking on the bottom of the sills (on the pinchweld) is quite acceptable for roadside tyre changes. You can easily see the spot welds on the bottom surface of the outer sill holding this reinforcement in place.

And here is the patch piece welded in from the donor car:

A small rust repair to the front of the sill and it's done.

Also have the fibreglass lower quarter panel extensions bonded in. I used an epoxy adhesive. Will last forever and forgiving of any surface imperfections when bonding. I'm really happy with how the extensions turned out once in place:

I've also pulled the driver's door off the donor car and fitted it so I could fair up the quarter panel to door gap. I knew the rear corner of the door had been repaired before, but I found out the whole bottom of the door had a very poorly done strip repair. It was the old lazy lap the repair over the top and bash it down, then hide with filler repair!

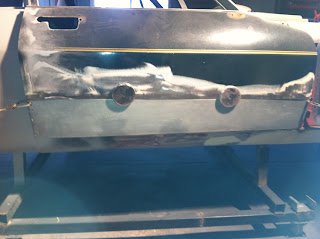

So I'm replacing the lower door skin to get rid of the horrible dents and waves, plus the rust. Best to do it whilst the door is still on the car so everything can be aligned in place:

The good news is that the weather is starting to warm up a little...if I catch a break, I may be able to get the body in epoxy primer in the next couple of weeks. I just have to go over the body and repairs with 240 grit, then spray some polyester filler over the repairs to fill any pinholes. Then epoxy (finally)!

I'd previously repaired and fabricated a new piece for the inner sill before replacing the floor panels.

So, we've gone from this:

A bit of pushing:

And here is the patch piece welded in from the donor car:

Also have the fibreglass lower quarter panel extensions bonded in. I used an epoxy adhesive. Will last forever and forgiving of any surface imperfections when bonding. I'm really happy with how the extensions turned out once in place:

I've also pulled the driver's door off the donor car and fitted it so I could fair up the quarter panel to door gap. I knew the rear corner of the door had been repaired before, but I found out the whole bottom of the door had a very poorly done strip repair. It was the old lazy lap the repair over the top and bash it down, then hide with filler repair!

So I'm replacing the lower door skin to get rid of the horrible dents and waves, plus the rust. Best to do it whilst the door is still on the car so everything can be aligned in place:

The good news is that the weather is starting to warm up a little...if I catch a break, I may be able to get the body in epoxy primer in the next couple of weeks. I just have to go over the body and repairs with 240 grit, then spray some polyester filler over the repairs to fill any pinholes. Then epoxy (finally)!

No comments:

Post a Comment